Manufacturing in the Commonwealth

Massachusetts invests in the infrastructure, training programs, companies, and people who are developing next century products.

For over 100 years, manufacturing has been a critical part of the Massachusetts economy. From the textile mills in Lowell to the metal fabrication plants in Springfield, the Commonwealth of Massachusetts has been a leader in developing and delivering cutting-edge products.

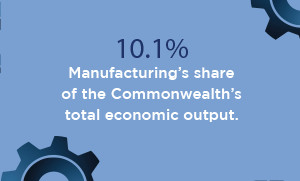

Today, the manufacturing sector employs more than 244,000 workers at 6,900 companies, representing nearly 7 percent of the state’s workforce. As the sector has evolved, wages have begun to reflect the increased demand for highly skilled employees, with manufacturing workers earning $18,000 more each year than the average worker in Massachusetts.

Manufacturing is poised to drive economic growth across the state in the coming decades. The Commonwealth of Massachusetts is making investments to help students and workers interested in manufacturing careers by providing critical skills training and investments in cutting-edge tools. The Commonwealth also helps small businesses stay competitive by providing critical financing for equipment purchases and facility expansion, spurring job growth.

MAmanufacturing.com offers students and employers information including financing solutions, business support and assistance, along with the latest manufacturing news and events. The state-run site was developed in partnership with the Advanced Manufacturing Collaborative, a group of manufacturers, business leaders, and public officials committed to developing and promoting programs to boost this critical sector.

The manufacturing sector is in the midst of rapid growth, driven by the advancement and integration of innovative analog and digital technologies into R&D and production processes. Manufacturers across the U.S. feel the impact of these enhancements, but especially those in Massachusetts, a state many innovative, forward-thinking companies call home. Increased use of new sensors, advanced materials, and automated technologies accelerates the pace of innovation, allowing firms to bring new designs to market – and to new customers – faster than ever before.

To help Massachusetts manufacturers and their employees stay at the front of this innovation curve, the Baker-Polito Administration made a $100 million commitment to invest in new technologies and product development via the Massachusetts Manufacturing Innovation Initiative, or M2I2, managed by the Massachusetts Technology Collaborative.

M2I2 invests in critical R&D infrastructure projects that bring together advanced manufacturing firms with the state’s top academic research institutions, providing capital grants to projects supported by the federal Manufacturing USA program, a network of nationwide institutes that aims to restore U.S. preeminence in manufacturing and bring new products to market.

While Massachusetts plays a role in nearly all the Manufacturing USA institutes, M2I2 is investing in four areas where Massachusetts has the potential to become a global leader:

- AFFOA (Advanced Functional Fabrics of America);

- AIM Photonics (American Institute for Manufacturing Integrated Photonics);

- NextFlex (focused on flexible-hybrid electronics); and

- ARM (Advanced Robotics Manufacturing)

The Baker-Polito Administration made a $100 million commitment to the M2I2 initiative.

The M2I2 effort looks to deepen the connection between manufacturers, researchers, and training programs, helping advance innovation and job growth in these areas. Product development will address several emerging global markets, such as business automation, construction, consumer goods, defense, smart fabrics, sensors, robotics, digital health, and the Internet of Things.

Investing in the future of Massachusetts manufacturing.

The state’s M2I2 program and the federal Manufacturing USA initiative have supported a wide range of projects, including:

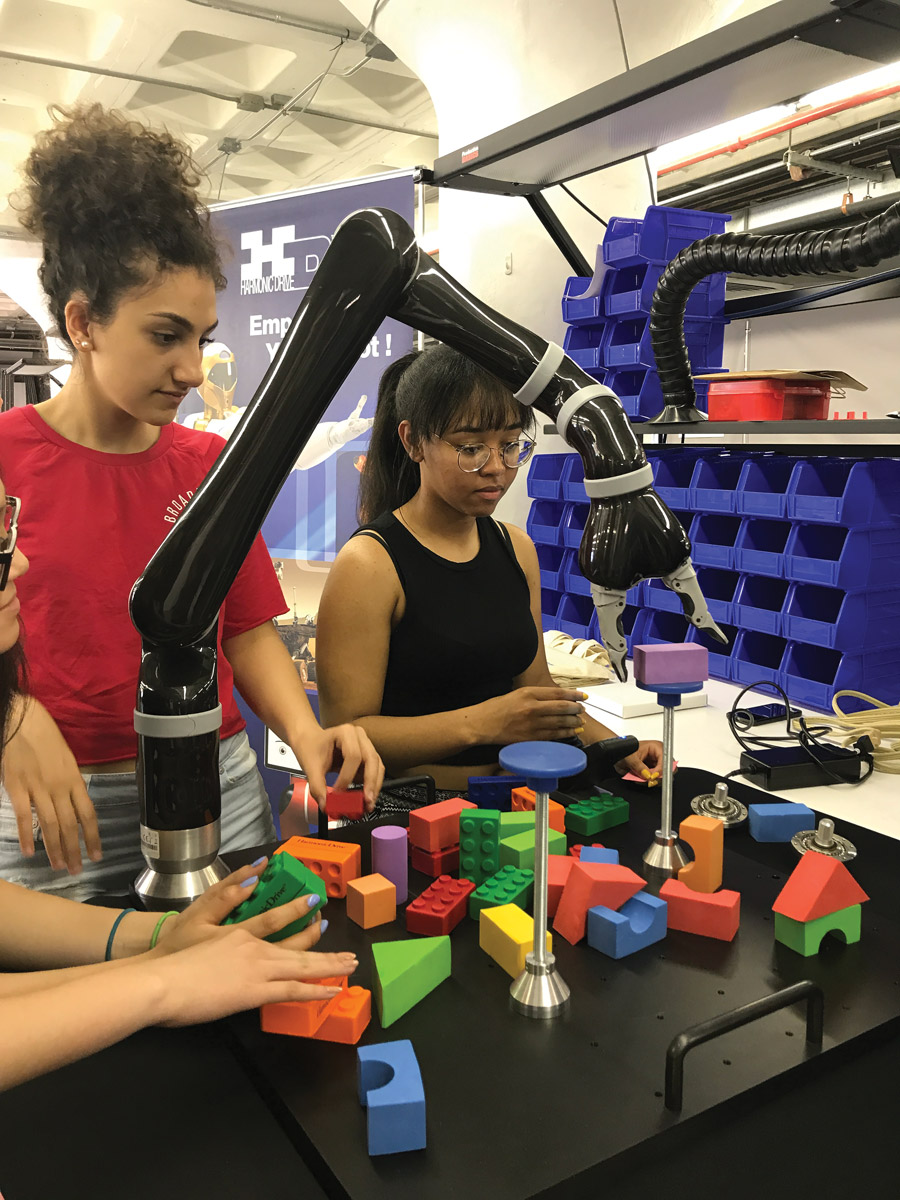

- Teaching Workers to Utilize ‘Co-Bots’: MIT and the MassRobotics accelerator are helping train Massachusetts workers to utilize collaborative robots in the manufacturing process using a system called “TeachBot.”

- Leading in Smart Building Materials: UMass Lowell researchers and Saint-Gobain are developing a revolutionary “optical fabric” that can be woven into major public works projects such as pipelines, bridges, tunnels, or rail lines. UMass Lowell is the only location in the United States that has projects supported by three national institutes (AFFOA, NextFlex, & ARM) in a single location!

- Developing Suits That Can Breathe: MIT and the clothing firm Ministry of Supply are using 3D-knitting to manufacture a new type of garment that can sense and adapt to the local climate, by changing garment breathability and body blood circulation.

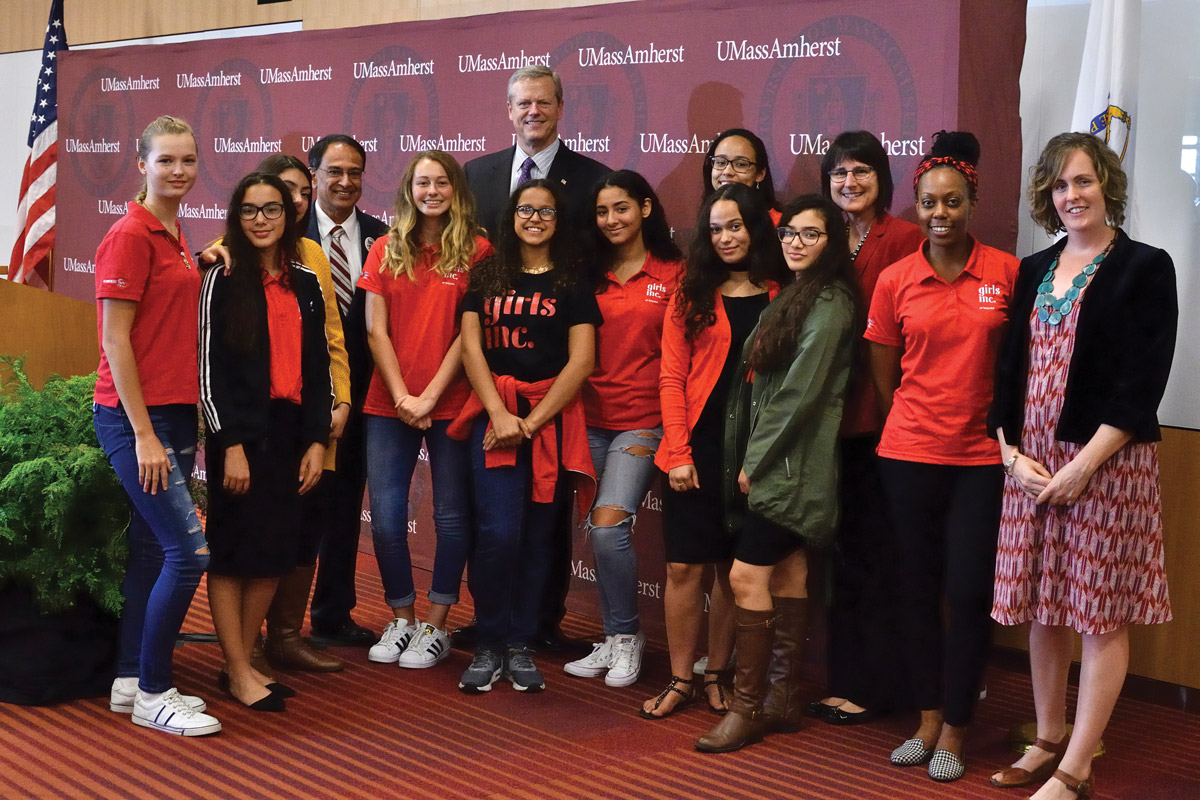

Students visit MassRobotics.

- Building the Eyes of AVs: Photonics provide critical sensing and information sharing capabilities in next-century products such as autonomous vehicles (AVs), homeland security monitors, and telecommunications. M2I2 has invested in key infrastructure at MIT Lincoln Laboratory in Lexington, one of the only facilities of its type in the U.S., which also hosts internship opportunities for students from photonics training programs at Springfield Technical Community College and Bridgewater State University.

By advancing R&D in these core areas of manufacturing, Massachusetts helps spur new company growth, create jobs, and develop revolutionary new products that succeed in the marketplace. Learn more about M2I2 and these projects on our website www.m2I2.masstech.org.

Manufacturers can visit www.MAManufacturing.com for resources and tools they need to succeed.

Providing financial resources and

real estate solutions for manufacturers.

MassDevelopment plays a hands-on role supporting manufacturers of all types across the state, providing everything from innovative loans for growth initiatives to long-term financing for real estate projects to help manufacturers grow their businesses and stay competitive.

- Equipment loans: On the North Shore, MassDevelopment provided a $225,000 equipment loan – and enhanced the loan with a guarantee – to Fleet Machine Company, an advanced manufacturing company in Gloucester. Fleet Machine used loan proceeds to buy a CNC horizontal machining center that will help the company increase production of components for the aerospace, defense, robotics, and medical industries.

- Tax-exempt bond financing: In western Massachusetts, MassDevelopment used tax-exempt bond financing to support precision machine company Valley Steel Stamp throughout various stages of growth. In 2018, MassDevelopment issued a $1.9 million bond to help the company build a 17,500-square-foot expansion to its Greenfield headquarters.

- Investment in ecosystem: MassDevelopment provided funding for the upcoming Berkshire Innovation Center (BIC), a 20,000-square-foot center at the William Stanley Business Park in Pittsfield. The BIC will offer shared access to technology, equipment, training, and more to help advance the manufacturing strength of western Massachusetts.

- Financial support: In central Massachusetts, MassDevelopment worked closely with WGM Fabricators and its lender to secure a $7.8 million financing package, helping the company move into a state-of-the-art facility in Whitinsville and purchase some of the most technologically advanced equipment in the industry.

In addition to offering innovative financing solutions, MassDevelopment plays an instrumental role in MAmanufacturing.com, connecting manufacturers with resources they need to grow in Massachusetts. MassDevelopment also launched the AMP it up! campaign to help middle and high school students learn about the many well-paying skilled manufacturing jobs available in the state.◾

Finicky Pet Food in New Bedford processes fish for the pet food industry. To reduce soaring electricity costs, the company worked with MassDevelopment on a financing package that enabled them to purchase and install solar panels. The investment in renewable energy has allowed the company to devote more resources to delivering high-quality products for its customers.