Cannabis company Garden Remedies, which runs a dispensary in Marlborough and a cultivation and manufacturing facility in Fitchburg, announced last month it has completed a $1.5-million capital expansion, resulting in a new extraction lab to ultimately increase the company’s ability to produce refined cannabinoid oil.

Work on the Fitchburg project began in July 2019 and, following a lengthy permitting and safety upgrade process, was officially up and running as of March 8 of this year, said Vice President of Lab Operations Gene Ray during a May tour of the facility.

The upgrade is a long time coming, said Ray, who originally hoped to be in the new extraction lab space by the end of 2019. But, when work on the project was delayed because of necessary safety modifications, combined with a temporary work stoppage due to the coronavirus pandemic, that goal was no longer a reality.

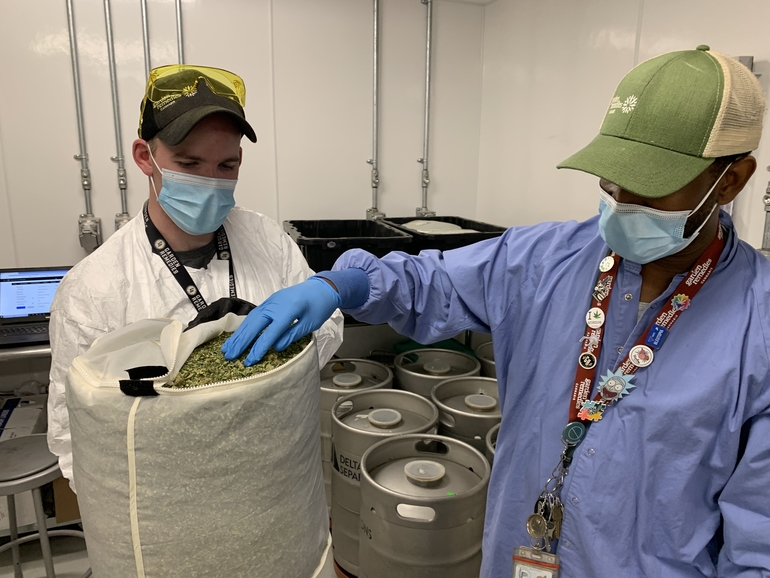

Nevermind the lab’s remaining older extraction machine went out of commission in November of the same year, resulting in more than 3,200 pounds of flower accumulating in the lab’s staging area.

“You can only imagine the frustration,” Ray said. “It was a tease to see all this shiny new equipment that you couldn’t even touch, couldn’t even use.”

But, now with the extraction lab is up and running, spirits are high and lab staff are making their way through the backlog of cannabis flower ready for processing. Ray said they were lucky to have enough refined oil to carryover during the temporary shut down.

He explained the lab uses a multi-step process to extract crude cannabis oil, which is then transferred to a separate lab for refining. Once refined, that oil is used either in the Garden Remedies kitchen to make edibles, or within the lab to produce goods like tinctures or vape cartridges.

A throughput analysis of the laboratory showed the Garden Remedies team was able to process more than 100 pounds of flower into refined oil in about seven days. Some 500 pounds of flower was processed in 20 business days, according to company figures.

Because of the high throughput, Garden Remedies will now be able to process oil for outside growers as well, effectively expanding not only its own production capabilities, but it’s business base, too.

This is useful for others, Ray said, like for growers who don’t have processing capabilities, or for those who have a damaged cannabis crop that can still be salvaged by turning the plants into oil.

Now, it’s a matter of moving forward — completing the processing backlog and making use of the lab’s new refined oil capacities.