Manufacturing institutes offer students and interns a chance to work on cutting-edge products

Peter Perez is working with a solar panel company to solve a problem.

“The current industry standard protective backsheet is reducing the efficiency of solar power all over the world,” Perez said.

Perez is part of a team trying to build a better, more efficient backsheet to improve panels’ efficiency and safety. But Perez is not an employee of the company or an engineering consultant. He’s a 21-year old senior at the University of Massachusetts Lowell.

All over the state, students in college, graduate school and even high school are working with companies and university research departments solving real-world high-tech problems under a broad umbrella known as Manufacturing USA.

Founded by the federal government in 2012, Manufacturing USA – previously called the National Network for Manufacturing Innovation – consists of 14 institutes bringing together industry and education partners. The state of Massachusetts has chosen to invest in four of them, and some universities in the state participate in some of the 10 other institutes.

Fabric Discovery Center

Location: Lowell

College affiliation: UMass Lowell

Founded: 2018

Purpose: To engage companies, researchers and students in the design and pilot manufacturing of high-tech fabrics and wearable electronics

Next-generation products

Perez is part of the Fabric Discovery Center at UMass Lowell, which opened this July. The center brings together three of the Manufacturing USA institutes: Cambridge-based Advanced Functional Fabrics of America, which is the only one of the institutes headquartered in Massachusetts, as well as Advanced Robotics for Manufacturing (ARM), and NextFlex, the flexible electronics institute.

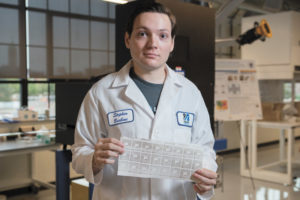

Stephen Burbine is working with materials at the Fabric Discovery Center to put sensors in clothes.

Photo / Matthew Wright

Siddhant Iyer works on plastics engineering and junior organic photovoltaics for wire coatings.

Photo / Matthew Wright

Ramaswamy Nagarajan, who helps lead the research at the center, said the point is to develop next-generation products like wearable electronics, temperature-resistant fabrics and wound-healing medical textiles, along with the automated production processes to make it practical to manufacture them in the U.S.

“The whole thing has been awesome all around,” Perez said, “To take experiments or results you get and then practically apply it to a product that’s being sold and marketed all around the world.”

Stephen Burbine, a 23-year-old graduate student who’s also working at the center in Lowell, said he’s been doing hands-on manufacturing tasks, creating new kinds of materials to be used to make flexible antennas or clothing with sensors. Burbine said he’s looking forward to a career as a plastics engineer, and he’s found working at the center, with its industry partners and state-of-the-art equipment, a worthwhile and challenging experience.

“Doing research is great,” he said. “You really have to be on your game.”

Peter Perez uses the Fabric Discovery Center to try and solve solar panel problems.

Photo / Matthew Wright

For Stuart Daudlin, a 22-year-old who graduated from the University of Michigan with a degree in engineering physics earlier this year, taking part in a Manufacturing USA program this summer was a step toward his goal of working in manufacturing.

“I was always interested in building new things – Legos as a kid,” he said. “I like to build things and see how they can affect other people and society.”

Jacob Bouchard, a student at Worcester Polytechnic Institute, attended the photonics summer academy at MIT.

Photo / Contributed

Ultra-fast light particles

The Future Leaders program Daudlin participated in is part of the American Institute of Manufacturing Integrated Photonics, or AIM Photonics. While the whole institute is based in Rochester, N.Y., its educational arm, AIM Academy, is headquartered in Cambridge and affiliated with the Massachusetts Institute of Technology.

AIM Academy

Location: Cambridge

College affiliation: MIT

Founded: 2016

Purpose: To offer education and workforce development in photonics, including summer and winter academies for students and industry professionals

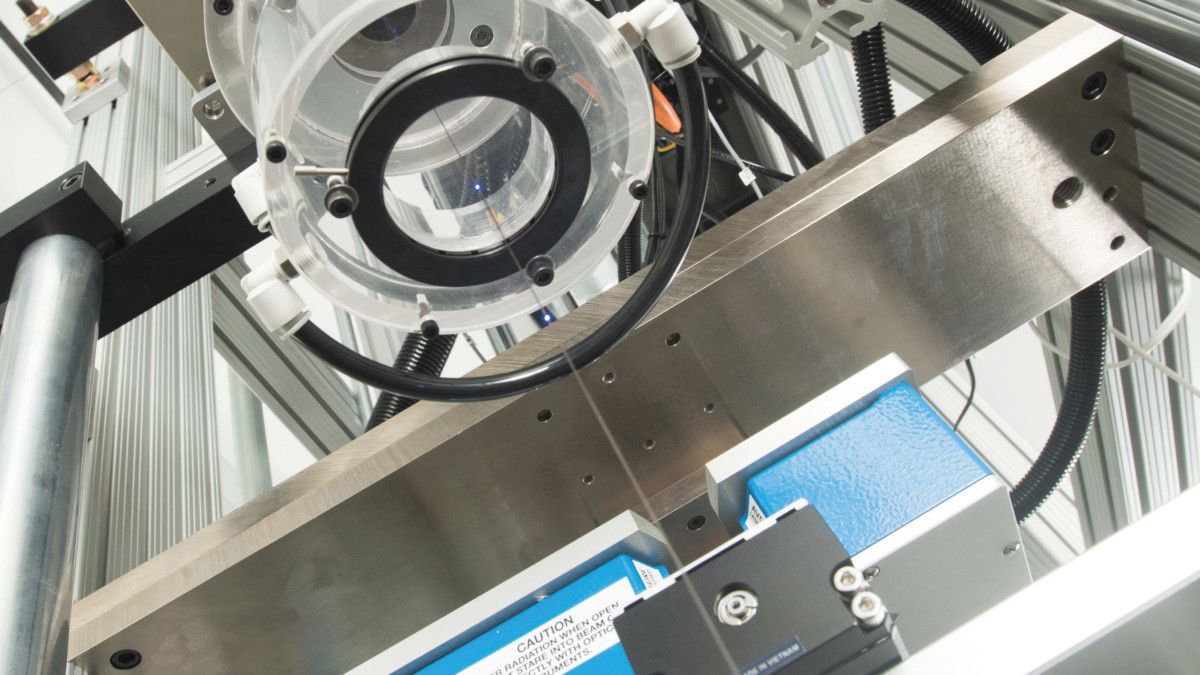

Julie Diop, program manager for the AIM Academy, said the discipline of integrated photonics involves using photons – ultra-fast light particles – for a range of tasks. Photon-based sensors can detect abnormalities in blood or impurities in water. Some photonic systems can replace electronic ones, moving data faster and more efficiently. Others offer a way of communicating between military planes, or between an ambulance and a street light that needs to turn green to let it through the intersection. LiDAR – light detection and ranging – devices bounce photons off objects to map three-dimensional objects, potentially changing the future of transportation.

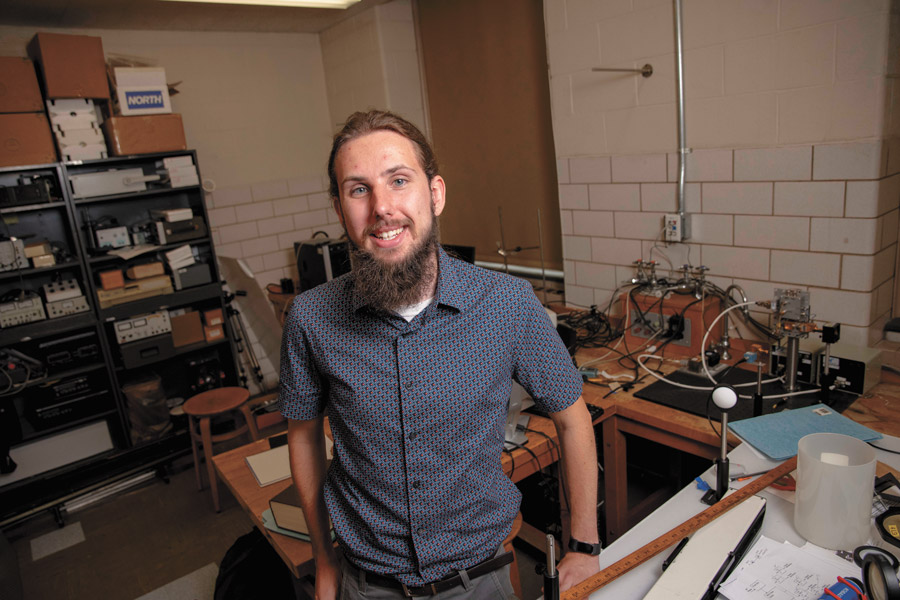

Stuart Daudlin

“Any kind of driverless car technology will be using this way of looking at surroundings,” Diop said.

Through the academy, Daulin took part in a paid internship, putting his theoretical understanding of physics to practical use building simulations and then sharing his work with other students at a conference.

“It was a good networking opportunity, a great work opportunity,” he said.

Working toward an

ultimate goal

Eric Pechinsky

Eric Pechinsky

This summer, Eric Pechinsky, now a senior at Greater Lawrence Technical School in Andover, worked in Cambridge at the Advanced Functional Fabrics of America headquarters.

“I got to see how they developed the fibers and put LED chips in them, and I got to analyze the defects in them to make them

come out more consistent and work consistently,” he said.

The high school is now working with AFFOA and other partners to create a pilot curriculum focusing on advanced fabrics.

Advanced Functional

Fabrics of America

Location: Cambridge

College affiliation: multiple

Founded: 2017

Purpose: To transform fibers, yarns and textiles into high-tech integrated and networked devices and systems

Pechinsky said he hasn’t been convinced a career in fabrics is for him, but he’s looking at a different kind of manufacturing: working in robotics for a military contractor like Raytheon. Like other participants in Manufacturing USA programs, he said he’ll take what he learned with him as he moves toward his ultimate goals.

“It was really cool to see the whole process behind how everything is done,” he said. ■