Want to see fighter jets? Head to the New England Air Museum in Windsor Locks to check out a very cool collection of fighter jets, including an F-100 dating back to the 1950s and is an early example of a supersonic fighter jet, and a Russian-built MiG fighter jet from the same era, said Ron Katz, the museum’s director of advancement and external relations. The MiG fighter jet line has been the mainstay of Russia’s fighter jet technology for decades, Katz said, and is very comparable to our fighter jets.

Connecticut makes engines for some of the coolest planes in the world

Even if you’re not a football fan or particularly patriotic, you’ve probably been wowed at the start of a Super Bowl on TV when fighter jets zoom over the stadium, putting an unmatchable exclamation mark on the singing of the national anthem prior to the start of the game. You can’t help but think about where those planes have been, or where they might travel to in defense of our country.

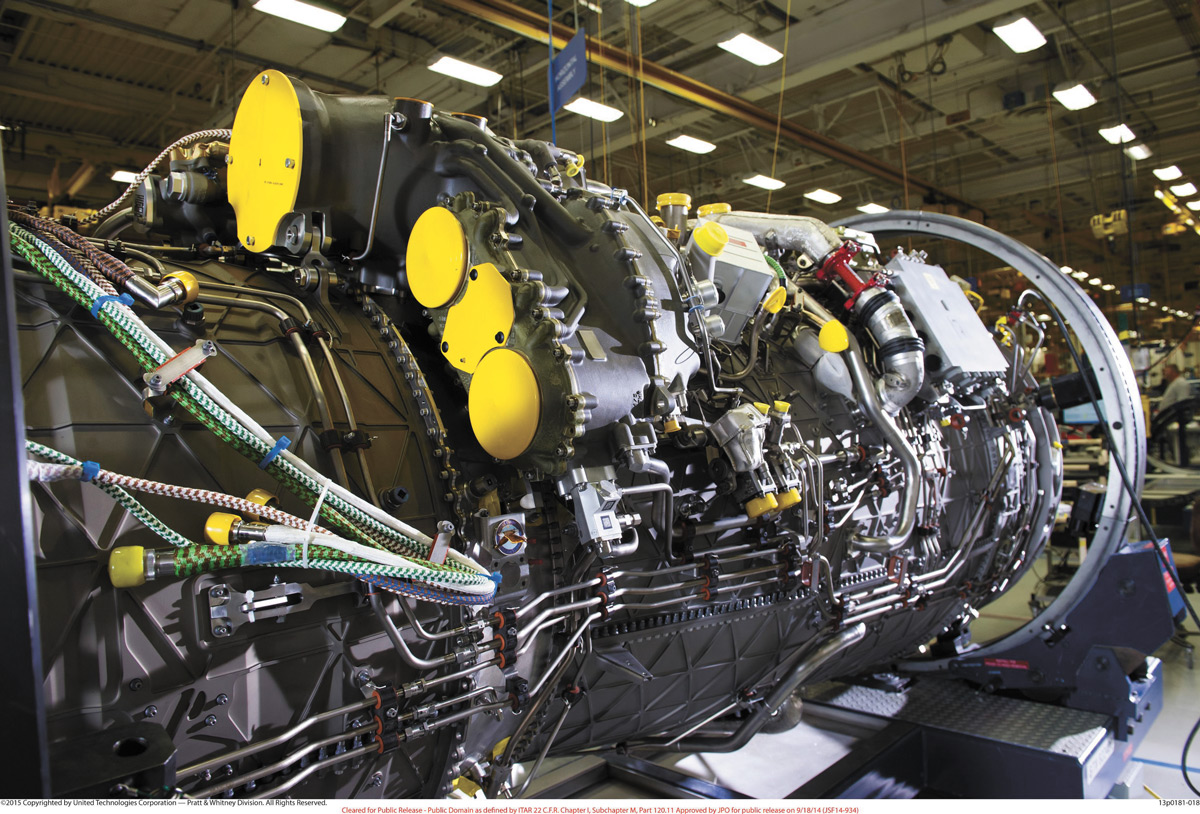

Connecticut manufacturers have long contributed to our country’s aviation industry, including fighter jets. In fact, aerospace manufacturer Pratt & Whitney, located in East Hartford, has been developing—and really, revolutionizing—the jet engines for decades, said Ron Katz, director of advancement and external relations at the New England Air Museum.

Connecticut overall has had “ significant impact on the engine technology, Katz said.

Kyle Ramsay is a Pratt & Whitney operator/machinist who works on vanes that affect engine airflow. He didn’t initially set out to work in manufacturing, but after earning an associate degree in criminal justice and struggling to find work, he ended up at a small machine shop.

“It was great,” Ramsay said. “I learned quite a bit. I was there just under four years and the pay was good. . . . When I heard Pratt & Whitney was hiring, I applied, and I was one of the lucky ones that got hired.”

Kyle Ramsay

Position: Operator/machinist

Company: Pratt & Whitney, East Hartford

Age: 27

Residence: Broad Brook

Salary range for this type of job: From minimum wage for entry level to $50+ per hour

A New England man: “I enjoy the outdoors. I enjoy living in the East Coast. I like the seasons.”

Ramsay works in a very clean environment, he said, and enjoys having the final touch on the product before it goes to final inspection. He also likes knowing that his work matters.

“We make a difference. Our final judgment makes a big difference,” Ramsay said.

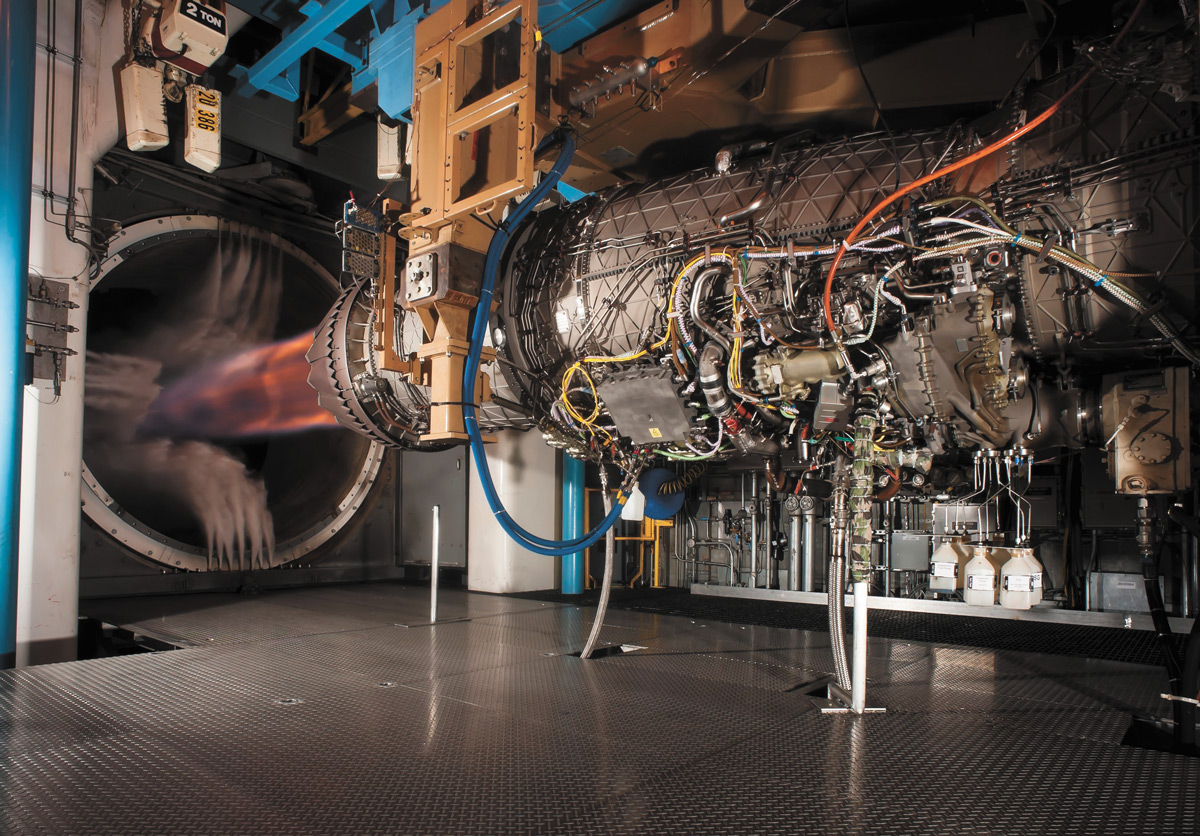

Pratt & Whitney tests jet engines at its Middletown facility.

Started at the bottom

In Eastford, Mark LaMountain is a business unit manager at Whitcraft, which manufactures parts for the F-35 fighter jet engines, as well as parts enabing the planes to take off and land vertically. As you might imagine, precision is key, along with quality, and the skill level of the people working on the parts.

LaMountain oversees an approximately 50-person team at Whitcraft. He began working in the aerospace industry at the age of 20, having been attracted by the industry’s reputation for job security. He worked his way up, starting on the production floor.

“The more I did it,” he said, “the more I learned to love it. . . . It’s enjoyable work, challenging work.”

LaMountain is particularly fortunate to work for a company investing in its employees, he said.

“The company pays for my college, they’ve put me through a year-long apprenticeship program, they sent me overseas to study. There’s a lot of opportunities to learn,” he said.

Mark LaMountain

Position: Business unit manager

Company: Whitcraft, Eastford

Age: 35

Residence: Putnam

Salary range for this type of job: About $75,000 for entry level, progressing to $100,000+ with experience.

Gap years: “I’m a bit of a traveler. I took a couple of years off to travel around the country.”

But he also enjoys the challenging nature of his job.

“Every day when you go in, there’s a lot of engineering problems to overcome, and we work . . . as a team to overcome these things,” LaMountain said.

The parts have grown more complex over time.

“It’s fun. If you’re into Legos and stuff, which I always loved as a kid, this is kind of like grown-up Legos. You’re trying to put them together and make them work,” he said.

Whitcraft employees take great pride in the fact that they’re doing military work.

“We know what we’re a part of, and we definitely keep that in mind,” LaMountain said. Fighter jets and their pilots “keep us safe, so we need to keep them safe by making good parts. . . . A lot of people [at Whitcraft] are really proud to be a part of the team that makes these engines that go into these aircraft that defend the nation.”

Krystyna “Krys” Paluch, owner and CEO of Phoenix Manufacturing Inc., a maker of precision aerospace parts in Enfield.

The significance of working in the aerospace industry is uppermost in Hollie Lehouillier’s mind. Lehouillier is a quality inspector at Phoenix Manufacturing in Enfield. She attended vocational school to be a machinist, but after working in that capacity for several years, she sought out a change.

“I realized that I wanted to know more about parts – what they do, and why,” Lehouillier said.

Her curiosity and eagerness to learn eventually led her to the quality side of manufacturing.

Phoenix is one of the cleanest shops she’s ever worked for, she said, and the technology is advanced. She enjoys knowing she is making a real contribution to the end product and beyond.

“I like to make sure that the products that are leaving the company are good,” Lehouillier said “I like to know about the part. I like to know everything about them. I like to know where they’re going, what they’re used for.”

Hollie Lehouillier

Position: Quality inspector

Company: Phoenix Manufacturing, Enfield

Age: 26

Residence: Chicopee, Mass.

Salary for entry level in the position: $15-18 per hour

What’s the WOD? “I’m a coach for CrossFit.”

And because “everything’s always improving and the technology’s always becoming much more advanced,” she said, “I always get to learn more about how something gets inspected and why.”

Lehouillier thinks about what her work contributes to – the safety and security of the country – with every part she inspects.

“I’m very critical when it comes to my inspections. I’m always making sure that everything is perfect,” Lehouillier said. “Everything that we inspect is a matter of life safety.” ◾