Reminders are all around you

In Maine, we celebrate “Manufacturing Month” to acknowledge the world of “making.” Look around you — at cars, phones, kitchen utensils, magazines, tools, street lights, clothes and boats. Nearly everything we touch in our daily lives is manufactured, from what we wear to what we drive to where we live.

The perception of manufacturing is a challenge and we continue to struggle with antiquated ideas of what modern manufacturing looks like. Manufacturing Month is the time where Maine celebrates the companies and individuals who create and shape the future of manufacturing.

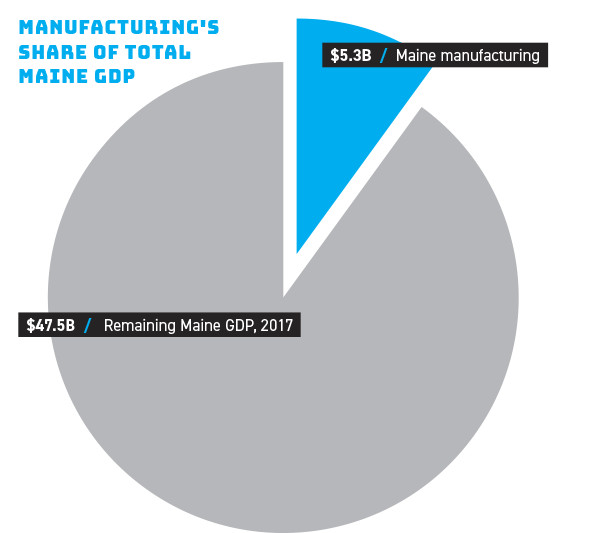

Maine is home to approximately 1,800 manufacturing business establishments and realizes over $5.3 billion dollars of the state’s total GDP. Manufacturing in Maine plays a critical role in the lives of people and communities, as well as in the operation of businesses.

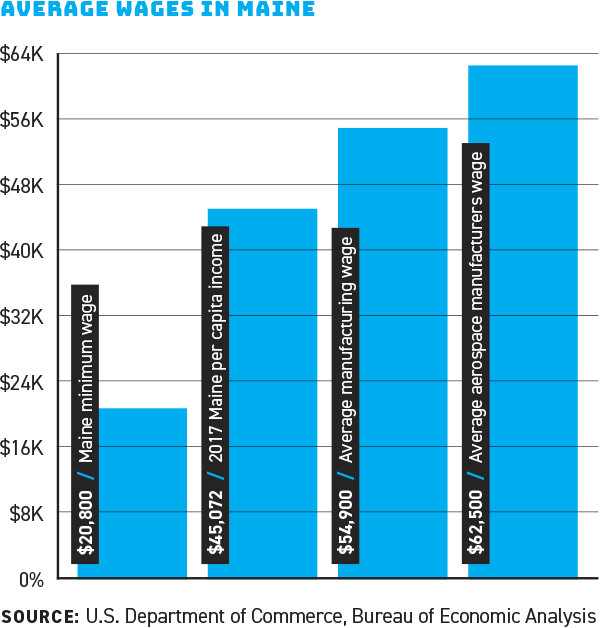

In Maine, manufacturing provides 50,900 jobs with a payroll of $2.7 billion, accounting for 13% of wages paid.

The average manufacturing wage in Maine is $54,900 — which is 32% higher than all industries in Maine. Aerospace manufacturers in Maine, making components for some of the world’s top companies, make an average wage of $62,500.

Manufacturing in Maine plays a vital role in global industries, including defense, aerospace, metal, paper, marine and boat building, semi-conductors, wood, textile, aquaculture, biotech, medical device, electronics, radio frequency and wireless communications, plastics, composites and bioplastics and food and beverage manufacturing.

The Manufacturers Association of Maine and its partner associations gather input on top issues and challenges from the full range of manufacturing sectors. The goal is to leverage the strengths of these organizations, avoid duplication of effort and promote a coordinated manufacturing support strategy.

For years, the annual Manufacturing Summit has produced a report highlighting the top issues and challenges for the manufacturing sector. And for several years running, the top concerns have been workforce availability, energy costs and the cost of doing business in Maine.

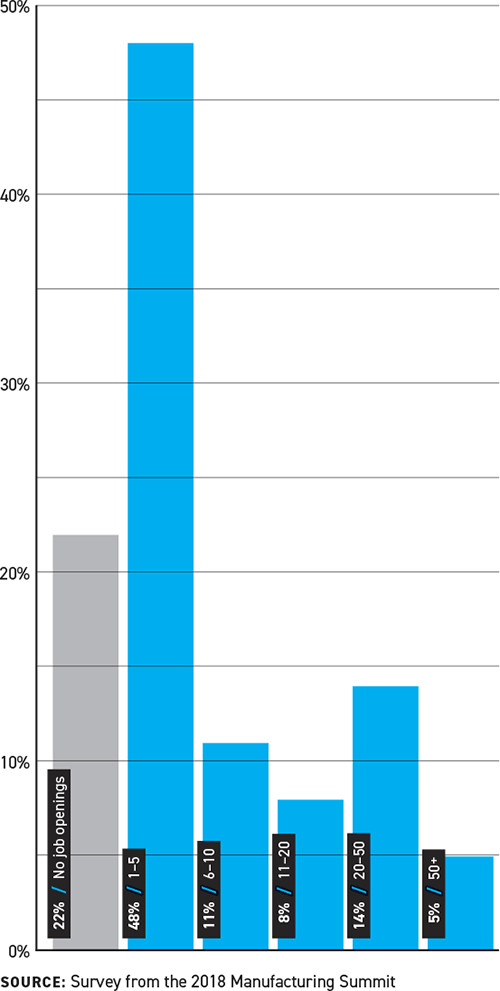

This year, manufacturers are struggling to find qualified workers (see chart on Page 8). That’s the No. 1 issue this year. Legislative and policy issues are also concerns, as are energy costs.

The association continues to have an impact by creating and implementing strategies on student and educator outreach and robotics programs, to employ transitioning military members, new Mainers/immigrants, corrections populations and others seeking meaningful employment.

As we work to promote careers in manufacturing, we must collaborate with industry, government, service organizations and workers to assure the retention and expansion of the manufacturing sector.

Our efforts to promote and grow manufacturing will create an environment where people, communities and businesses thrive. ■

Manufacturing jobs

From the 2018 Manufacturing Summit, a survey of companies showed the following job openings.

“In Maine, manufacturing provides 50,900 jobs with a payroll of $2.7 billion, accounting for 13% of wages paid.”

Mountain Machine Works CEO, Bruce Tisdale

Mountain Machine Works, Auburn

Mountain Machine Works in Auburn offers a range of machining services and contract manufacturing, much of it custom-fitted to the needs of manufacturers. The company has about 25 employees. ■

Front Street Shipyard, Belfast

Front Street Shipyard in Belfast offers a wide variety of services. It is a custom boat builder, a service yard and marina. It has a boat hoist with a 485-ton lifting capacity. It builds custom yachts as large as 200 feet. Construction approaches range from classic wood techniques to advanced composition solutions. The shipyard has a range of employees, with skills in carpentry, electrical systems, electronics, fiberglass and composites, IT and computers, metal fabrication, rigging and painting. The shipyard covers several acres on the Belfast waterfront, but is about to start on construction of 22,500-square-foot building (pictured) that will accommodate yard yacht refits and commercial vessel construction. ■

Thos. Moser craftsman Jim Wisser with a rotating clamp carrier.

Thos. Moser Handmade American Furniture, Auburn

Thos. Moser Handmade American Furniture in Auburn has made furniture for the George W. Bush Library in Dallas; Grace Farms, a nonprofit with innovative Japanese architecture in New Canaan, Conn.; and the Museum of the American Revolution in Philadelphia. But the bulk of its larger customers are institutions like university libraries or an MIT science lab, corporations and law firms. In recent years, Moser instituted “lean” building techniques. Instead of stockpiling inventory, it builds much of the furniture after it has been ordered, saving on warehousing. It has 55 craftspeople and about the same number on the support staff. Craftspeople are adept at using CNC machines and power planers, as well as traditional hand tools. ■

Paul Seymour, left, is instructed in how to bend pipe to Navy specifications by veteran pipe fitter and trainer Todd McPhee.

Bath Iron Works, Bath

Bath Iron Works, which is on the Kennebec River in what’s known as the City of Ships, has roughly 5,700 employees. Since 1884, it has delivered more than 425 ships for both naval and commercial use. It builds Arleigh Burke-class of guided missile destroyers, Zumwalt-class guided missile destroyers, as well as smaller frigates. The company is owned by General Dynamics Corp. (NYSE: GD), which has more than 100,000 jobs worldwide. (General Dynamics also owns an ordnance-and-tactical systems site in Saco.) A recent job listing included advanced concepts engineering project manager, assistant foreman/shipfitting, associate engineer, designer first class, electrician II, front line supervisor, engineer, manager/electrical engineering, pipefitter, to name just a handful of positions. ■

Portsmouth Naval Shipyard, Kittery

Portsmouth Naval Shipyard has 6,450 employees and had a total economic impact of $751.8 million in 2017. It is one of four federal shipyards and is overseen by the U.S. Department of Defense. Established in 1800, Portsmouth Naval Shipyard built submarines until 1971, when it switched to maintaining, repairing and modernizing nuclear submarines. In the past year, it has hired workers for a range of positions, including chemists, electrical workers, engineering, insulation, mechanics, pipefitting, radiological workers and sheet metal workers. ■