Zildjian workers shape cymbals through a precise manufacturing process.

Early in their careers, young manufacturers want to follow their passion and work with fun products and machines

Zildjian Cymbal, an American company tracing its roots back to a 17th century Armenian alchemist who made cymbals for the Ottoman army in Turkey, still uses a lot of its ancient secrets to make cymbals today, in Norwell.

But lathe operator Jason Mercier says the equipment and processes have changed.

“Obviously, they modernized some of the things … just to keep consistency,” Mercier said.

First manufacturer gig

He describes the process as a mix between machine automation and a hand-crafted artisan touch.

Mercier, who plays drums and guitar, took the job at Zildjian after finding an online posting. He’d previously worked restaurant jobs.

This is his first manufacturing job, and Mercier, who grew up with music, says it’s a good fit for him.

Jason Mercier, 26

Lathe operator

Company: Zildjian Cymbal

Company location: Norwell

Lives: Abington

Education level: High school diploma

Salary: $17/hour

Prior to operating the lathes, Mercier worked in the rolling mill, which thins the metal. After the metal is heated it in ovens, it’s put through rollers multiple times to get it to the right size.

Then it’s cut, hammered and pressed, Mercier said.

“When it comes to the lathe, you shave it off with a chisel by hand, break off the oxidized metal,” he said.

The point is to smooth out the metal and get rid of the grit and other imperfections.

Manufacturing employees work in a variety of conditions and often have the opportunity to wear more relaxed clothing.

Since starting his job at Zildjian, Mercier said he’s grown to really like it. He learns a lot and there are many ways to move up in the company, operating different tools and learning new techniques.

“People don’t really think about manufacturing. People don’t think it’s as available as it is,” Mercier said.

The work can be repetitive, but people don’t mind that, he said. Conversely, it’s a consistent job that never seems to slow down. Some employees have been at the company for 50 years, Mercier said.

“They treat us really well,” he said.

For example, Zildjian hosts free golf and dinner outings, as well as an annual boat cruise, Mercier said.

And Mercier still has his music. The job has given him a greater appreciation for what goes into it

Follow your passion

Engineering undergrad Patrick Davis likes the kind of work where he can be hands-on, a tendency he probably developed growing up on a family farm in Maine.

“I’ve always really liked mechanical systems and building things,” Davis said. His family’s farm is Davis Dairy, just outside of Bangor, Maine.

Patrick Davis, 20

Applications engineer intern

Company: Building Envelope Materials

Company location: Amesbury

Lives: Medford

Education level: Senior at Tufts University

Salary: $18.50/hour

Currently, he’s a senior at Tufts University in Medford, studying mechanical engineering. When he initially enrolled, he was in the biomedical engineering major, but soon realized that was too abstract, and changed his major to the more tangible mechanical field.

This past spring, he was looking for a summer internship by searching for startup companies on the website for Greentown Labs, a Somerville-based technology incubator with a manufacturing initiative.

That’s when Davis came across Building Envelope Materials, a company that makes and installs a minimally invasive retrofit insulation for buildings.

He reached out to the company’s founder, Doug Lamm, and set up an in-person meeting.

Davis accepted an offer to be a paid intern and worked for the company in various capacities from mid-May to the end of August.

What stood out to Davis about the company early on was its mission.

“I really liked what BEM was doing,” he said.

Davis said the insulation technology was not only good for property owners because it helps them save on energy costs, it is also good for the environment.

Davis also liked being able to get his hands into different aspects of the small company, from working with microcontrollers to the installation process to figuring out an outline for the manufacturing process.

He credits a lot of those opportunities to the fact that BEM is a small startup.

“It was super cool,” Davis said. “Not something I had experience with, but very interesting.”

He said he learned a lot from the experience, especially by seeing the business side of engineering “you don’t get exposed to in engineering school.”

Ultimately, he’d be happy to work at any company, big or small, as long as it applies useful engineering as a way to benefit the greater society, Davis said.

Though pay is a top concern he said, given the high cost of living in Massachusetts and the student debt he is accruing.

His advice to other young people getting into the industry is to look at the mission of the company that’s offering them a job. If it’s not something they can get passionate about it, they shouldn’t work there for long.

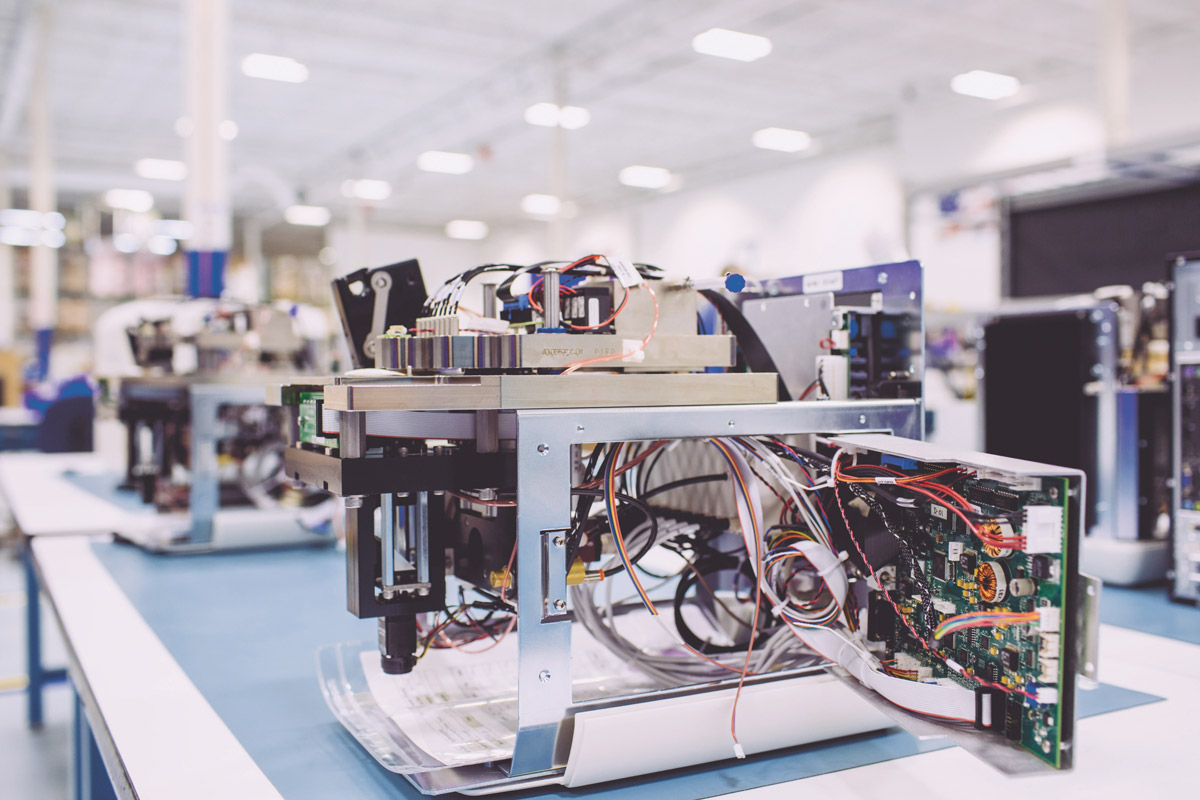

Making full-body scanners

Ryan Mannion has been working at Coghlin Companies for five years, accepting a job there straight out of college.

Mannion became enamored with the company ever since he got a tour of the company and saw the innovations for hardware companies the firm was deploying, and met with the CEO and President Chris Coghlin, a fourth-generation business owner.

“Some of the products we were working on were very cool,” Mannion said.

He said those innovations were impacting people’s lives in ways they wouldn’t normally notice.

Coghlin Companies provides contract manufacturing services to a diverse array of device and equipment manufacturers and select entrepreneurs. Mannion said the term contract manufacturing doesn’t quite do justice to full range of what Coghlin does to help partner companies scale up.

Some of the products the employees work with include body-scanners for security, automated warehouse fulfilment systems and medical devices, according to Mannion.

Mannion had worked in other industries with internships at an oil and gas company and a property management company, but neither were as fulfilling as working in manufacturing. He said he likes being able to work with new technologies.

Ryan Mannion, 27

Business development specialist

Company: Coghlin Companies Inc. Company location: Westborough

Lives: Boston

Education level: Bachelor’s degree in business

Salary: Mean annual salary for wholesale sales representatives in technical manufacturing in Massachusetts was $96,570 in 2017, according to the U.S. Bureau of Labor Statistics.

Cogmedix, a Coughlin company, offers a cleaner version of the manufacturing environment.

Coghlin Cos. creates complex machines.

As business development specialist, it’s Mannion’s job not to work directly on the production process, but to find companies who need to scale up and can use the services Coghlin has to offer. Unlike other contract manufacturers, Mannion said Coghlin is able to foster a stronger one-one-one relationship with its strategic partners.

He finds clients by creating a list of companies in growing industries and calls them to see what their needs are.

His advice to other young people getting into manufacturing or building a career in the sector is to be persistent, network with local firms to find opportunities and demonstrate your passion in the work.◾