Connecticut manufacturers pay employees to get training and degrees

In the spring of 2018, Walmart made national headlines when the retailer said it would pay for employees to obtain business degrees. These types of tuition assistance and educational-reimbursement programs are in vogue thanks to high-profile businesses like Amazon and Starbucks wanting to improve the quality of their workers’ training.

In Connecticut, the business consulting firm CONNSTEP has helped manufacturers to embrace new markets and upgrade the skills of incumbent workers through trainings in lean continuous improvement, business growth and workforce development.

“It’s amazing to work for a company, born right here in Meriden, that’s grown into a globally recognized brand, operating out of a 120,000-square-foot building and employs 190 people,”

— Kevin Scarpati

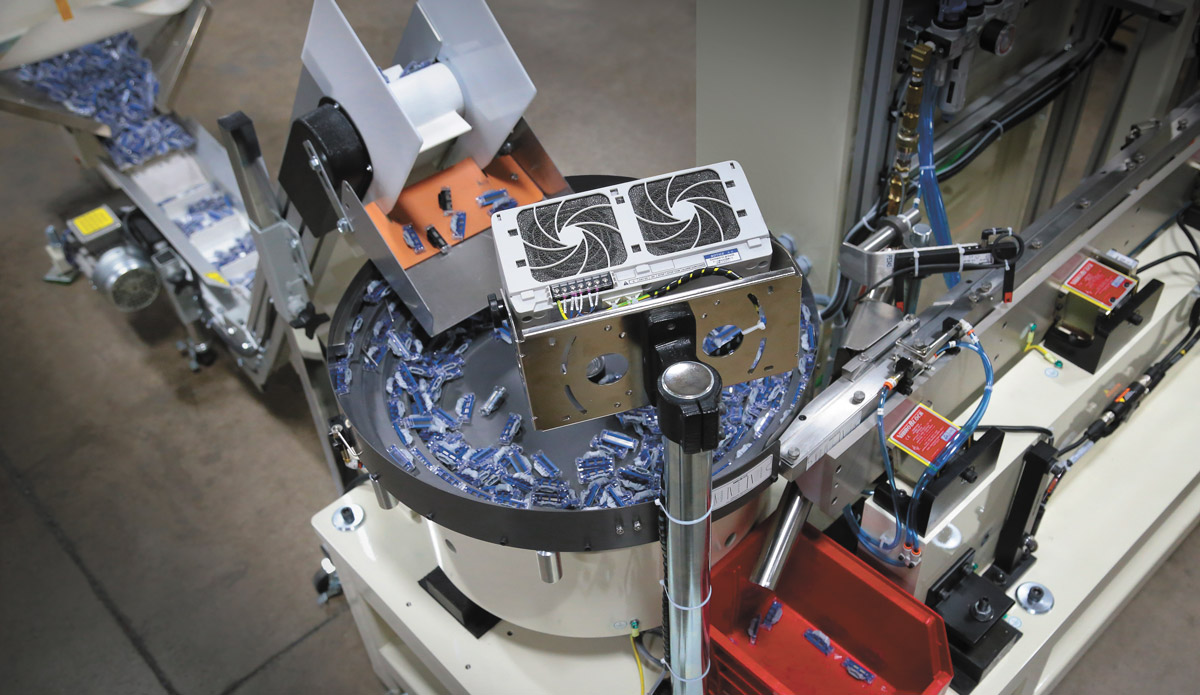

Arthur G. Russell Co. feeds medical products through equipment like this tower feeder.

Across the state, educational institutions and manufacturers are working together on the local or regional level to create brand new programs.

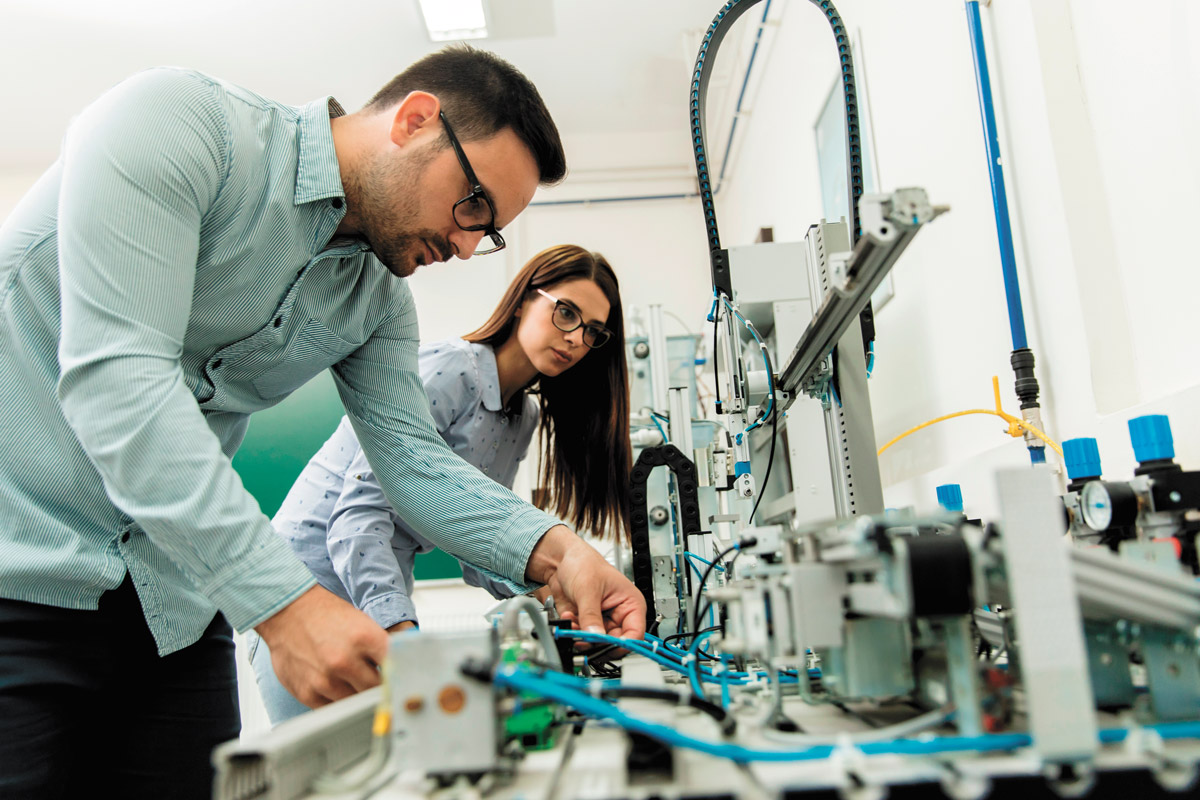

“We are working with area colleges and schools on developing a Mechatronix program that will provide a specific knowledge base for what we do. As a result, electrical and mechanical assembly will be addressed in one curriculum,” Ensminger said. “Also, our control engineering manager is working with a state college to build a relevant curriculum to meet our needs for electrical engineering.”

Russell was pleased to find that an academic faculty more than willing to put together an impactful curriculum based on the input of manufacturers.

Arthur G. Russell Co.

Location: Bristol

Main product:

Automated assembly systems

Employees: 160

Employee education program:

On-site mobile college courses, lean training, college-tuition reimbursement program, apprenticeships and internships, and curriculum development at the university level

“We offer our employees 80-percent tuition reimbursement towards a college degree with a grade of C or better,” Ensminger said. He sees older employees embracing these opportunities to advance their skills as well, including those moving into the next stages of their manufacturing careers.

“Some of our tenured employees are taking advantage of these opportunities as well. We have a manager and an executive who just completed their (master’s degree in business administration),” he said.

In some cases, colleges are even establishing a physical presence at the workplace.

“Goodwin College has a mobile classroom that they bring to your business for the purpose of employee training,” Ensminger said. “We hosted classes at the start of the month, and we plan on more courses going forward.”

High schools are also doing their part to ensure a new generation of manufacturing professionals will be at the ready when the workforce turns over.

Arthur G. Russell Co. seeks to offer students hands-on experience with products like this vibratory feeder.

“We also sponsor a First Robotics team with the hope to catch the interest of middle- and high-school students. Many of our employees volunteer their time to mentor the robotics team,” said Ensminger.

Innovative manufacturers like Arthur G. Russell Co. serve as exemplars for others looking to empower employees through education.

“In the custom automation business, it’s challenging to find employees that have the essential skills for what we do,” Ensminger said. “We have accepted the fact that we will have to develop our own employees by providing the necessary mentoring, assistance and training.”